Corn fabric for sustainable fashion

A Japanese chemical firm develops next-generation sustainable materials using plant-based fibres to help drive towards carbon neutrality.

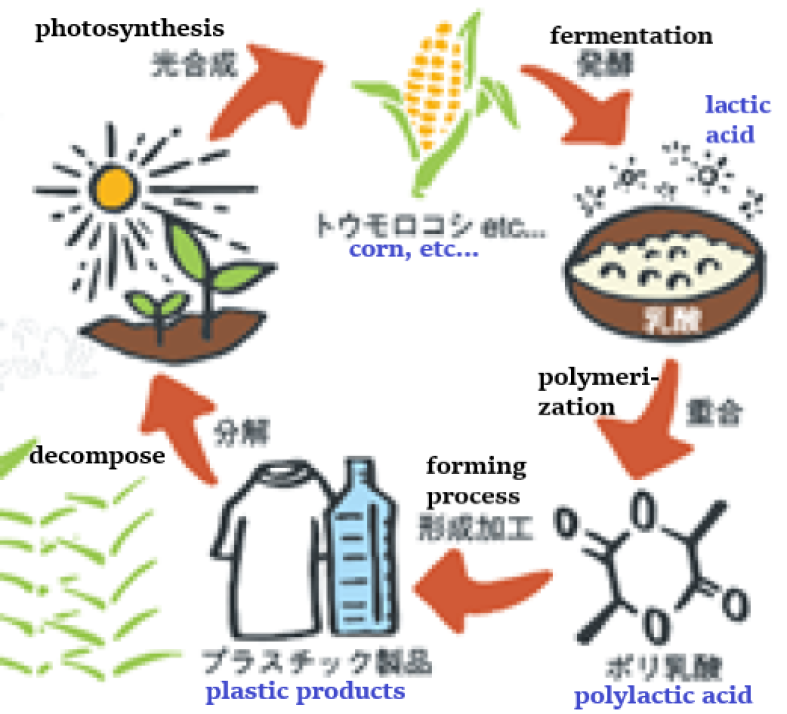

HIGHLACT by HighChem Co., Ltd uses polylactic acid (PLA) fibres made from corn.

PLA is a biodegradable plastic. Typical petroleum-based plastics can take between 100 – 1,000 years to break down naturally. Biodegradable plastics, meanwhile, can break down into water and carbon dioxide (CO2) by micro-organisms under certain conditions in much less time.

PLA is from biomass materials such as corn. Plants absorb CO2 as they grow. Although burning up plants releases CO2 into the atmosphere, the total emissions of this cycle are zero. That is what we call carbon neutral.

PLA has a simple chemical structure compared to standard plastics. Because of this, its strength and heat resistance are low. HighChem developed a process using an original plant-based modifier to improve a weak point of PLA—its heat resistance. Thus, PLA’s heat resistance, which averaged 59°C, has significantly improved to an average of 145-150°C, leading to the birth of a completely new product.

And now, Hichem has teamed up with an established almost 100-year-old Japanese textile manufacturer to achieve a successful mixture of traditional methods.

Creating a next-generation sustainable material is one of the solutions to the fashion industry’s challenges of mass production, mass consumption and mass disposal.

We have a network of Japanese companies keen to expand into the Halal market in Malaysia & Indonesia.

If you are interested in connecting with sustainable technology companies in Japan, simply JOIN the network from below. We will match the right one for you!